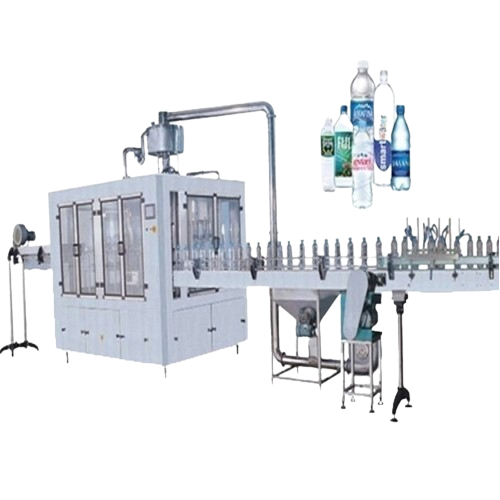

Water Filling Machine

Bottling clean water requires more than just filtration. It requires precision, hygiene, and speed. A Water Filling Machine offers a full solution for filling, sealing, and packaging bottled water. It does this efficiently and keeps strict hygiene standards.

Water Filling Machine – Efficient Bottling Solution for Clean Water Production

Whether you run a small business or a larger plant, this machine helps you increase production while keeping quality high.

We offer fully automatic, semi-automatic, and rotary systems. This makes it easy to find the right bottle filling machine for your production needs.

How the Water Filling Machine Works

The process begins with bottle handling. Workers either manually place empty bottles or the system automatically feeds them in, depending on the configuration. From there, the machine performs multiple operations in a smooth, continuous flow.

First, we rinse the bottles internally to remove dust and contaminants. Next, precise filling valves dispense measured quantities of purified water into each bottle. After filling, the machine seals bottles using secure caps to prevent leakage and contamination.

Because all stages operate in synchronization, the system maintains consistent output and reduces human contact. This improves hygiene and minimizes production errors.

System Configurations Available

This mineral water filling machine is available in multiple configurations. Local and imported 3-in-1 automatic filling lines combine rinsing, filling, and capping in a single unit. Rotary systems support higher output for large-scale operations. Semi-automatic machines offer flexibility for smaller plants or startups.

Packaging systems can also be integrated. Full-auto and semi-auto packing machines prepare bottles for storage and distribution. Optional laser printers add batch numbers and manufacturing details for compliance and traceability. PET blowing machines allow on-site bottle production, reducing dependency on external suppliers.

Built for Commercial Reliability

Each machine is constructed using durable materials and food-grade components. The design supports continuous operation with minimal downtime. Controls are simple, making daily operation and maintenance straightforward.

Moreover, these machines adapt easily to different bottle sizes such as 500ml, 1 litre, 1.5 litre, and 19-litre containers.

Where This Machine Works Best

This system is ideal for mineral water plants, beverage companies, commercial bottling units, and packaged drinking water businesses. It suits both new ventures and expanding production lines.

In short, this bottle filling machine helps you produce clean, professionally packaged water efficiently and consistently. It is a critical investment for any serious water bottling operation.